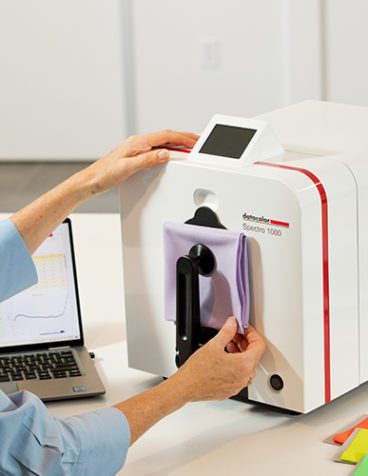

Today, the global textile industry uses spectrophotometers to measure digital color data. A common color language and protocols let retail and branded apparel companies specify colors that can be executed accurately anywhere in the world. Using the data, retailers and their global supply chains are able to maintain color consistency, a key quality indicator for textiles. The production cycle is faster, and costs are lower.

To meet expectations, though, color data must be accurate, and that means spectrophotometers must be accurate and reliable. For some, the answer is to “profile” their spectrophotometer. But how effective is instrument profiling in ensuring accurate and reliable data?

With so much riding on the reliability of reflectance data, Datacolor decided to perform a series of tests to answer the question, “Will instrument profiling ensure the accuracy of my reflectance data?”

Comparing instruments to a reference standard

Instrument profiling is a procedure that compares a user’s instrument to a reference instrument by measuring a set of ceramic tiles on each. Based on the differences between the two instruments, an algorithm is created to compensate for those differences. These mathematical adjustments can then be applied to all measurements made by the user’s instrument. Theoretically, the adjusted reflectance curves from the profiled instrument will then agree much more closely with the adjusted curves from another profiled instrument.

But how do improvements based on reference standards compare with improvements on actual textile samples? The only way to answer that question is to measure textile samples on instruments with and without profiling.

Our test

For a real-world test of improvements in instrument agreement, we performed a total of 2016 measurements of a variety of samples on Datacolor 600 (now Datacolor 800) spectrophotometers and on another company’s high-end instruments.

Study set

42 test samples

- 22 textile samples

- 12 ceramic BCRA samples

- 4 plastic tiles

- 4 paint cards

8 instruments from each manufacturer

- Diffuse/8 (sphere)

- Bench top (lab grade)

3 sets of measurements

- “As-is” – no profiling

- Profiled with Datacolor’s profiling software

- Profiled with the other company’s profiling software

Reflectance data evaluation

- We compared each measurement to an average (mean) by instrument manufacturer and as a single group

- We compared each instrument in the population to a specific instrument from each manufacturer

- We compared changes in DEcmc of individual samples before and after profiling

- Each analysis was performed using the entire data set, with the BCRA tiles alone, and with the textile samples alone. Needless to say, this was a very thorough evaluation.

Test results

- Instrument diagnostic tests are critical, specific to manufacturer, and best performed by the manufacturer’s software

- Both profiling programs improved inter-instrument agreement on BCRA tiles, but with consistency only for their own instruments

- The instrument diagnostic routines of the two profiling programs did not identify problems with the non-native instruments

- Profiled performance numbers from real-world textile samples will be worse than those obtained from ceramic tiles used for profiling

- Overall, improvements in agreement based on ceramic tiles were not matched by improvements in textile agreement

- If the improvement on ceramic tiles was greater than CIELAB DE0.15, there was some improvement in textile agreement, but only for specific instruments

Greater sources of error

Although instruments can cause some variability, previous studies indicate that they only account for about 10% of total inter-instrument agreement errors. Consequently, improvements gained by profiling a properly functioning spectrophotometer are relatively insignificant. It’s much more likely for improper measurement techniques and poor sample conditioning to create errors.

I’m happy to share my expertise to help you design state-of-the-art processes that ensure the color data you depend upon is as accurate as possible.

Ready to learn more about Datacolor? Contact us!