Improved color management can help fashion brands shorten lead times and remain competitive in an industry where speed to the consumer is critical. Two interrelated factors can significantly affect how efficient the design-to-consumer cycle will be:

- Objective color measurement

- Mill management

Brand Color Management

Designers find inspiration everywhere, and colors and color palettes are key design elements. Executing color is a science as well as an art, however, and not every color can be produced as the designer envisions. Chemistry limits which colors can be applied successfully to particular fabrication. And the number of specialty fabrics available – for sportswear and exercise gear, for example – is growing.

When color specialists work with brands at the design stage to explain technical limitations and help specify feasible palettes, the entire production process is accelerated.

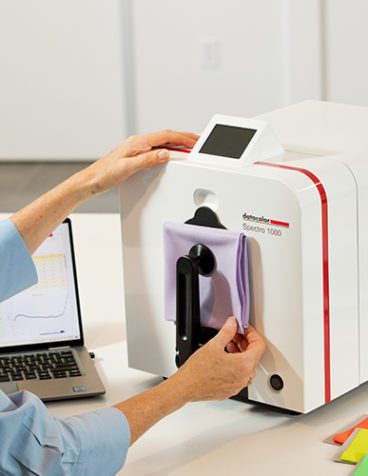

Specialized instruments and software transform measurement, assigning precise, repeatable, objective characteristics to colors and facilitating communication. Not only does this ensure colors will match, it can remove much of the time delay on the production end.

Even though the benefit of digital color management is widely accepted in the industry, more than half of the products are still being evaluated manually with subjective visual assessment methodology. This is due to the currently solution limitations on measuring non-solid colors.

Mill Color Management

When color measurement is done manually, the color development process can span several weeks or months. The need to create and ship physical samples for approval result in significant costs and time delays.

With objective digital color measurement, brands quickly build trust with the mills such that they can go to production immediately without fear of inconsistent color. Certifying mills approve their own colors and provide real time data to brands for tracking purposes. In addition to radically shortening the workflow, mills are then free to focus on other issues that improve quality of the finished garment or product.

The shortened production cycle makes brands considerably more agile in response to fashion trends and customer preferences. For instance, a brand might create a sweater in limited runs of several colors. If one color isn’t selling as projected, production can be quickly and easily shifted to the others. This reduces excess inventory while still ensuring retailers are able to meet customer demand.

Why the hurry?

Every business benefits from efficiency and agility, and that’s especially true for fashion. The State of Fashion 2018 report from The Business of Fashion and MacKinsey & Company relies on industry data and executive interviews to assess industry trends and challenges.

Survey respondents identified dealing with volatility, uncertainty, and shifts in the global economy as their major challenge for 2018. Value chain improvement and digitization was cited third.

Also according to the report, areas identified for cost improvement are to reduce product assortment complexity and pursue end-to-end efficiencies – second only to review of organizational structure and an increase in employee productivity.

As the report discusses, fashion was once seasonal, designer-driven, and marketed to and through retail outlets. Now fashion trends are increasingly customer-driven and can spread through social media channels overnight.

Partnering With An Expert in Color

While the industry overall continues to grow, online shopping poses a real challenge to brick-and-mortar stores and emerging markets in Asia and South America, not the west, dominate apparel and footwear. In this less predictable environment, brands need to be highly flexible and responsive.

Objective color management systems from Datacolor add efficiency to the supply chain. Measurement and control solutions ensure consistency. Tools like the ColorReader Spectro, currently oriented toward paint matching, are being adapted to textile standards and will be tied to feasibility tools. Our tools provide accurate color measurement and our software lets you communicate and display those measurements to stakeholders and suppliers.

Most important, we have the broad expertise necessary to be true partners. Our team includes industry experts familiar not only with color science but with textile industry workflow so we’re uniquely positioned to help our clients improve quality and meet their business goals.