No one enjoys dealing with the aftermath of a mis-tinted paint order. These errors are not only time-consuming to correct but also impact profit margins and diminish customer trust in your products. For paint retailers, avoiding mis-tints is essential to maintaining operational efficiency and ensuring customer satisfaction.

To help minimize these costly and frustrating errors, we’ve compiled five proven strategies that can effectively reduce mis-tints and support a smoother, more reliable paint-matching process.

1. Ask Questions

Go over the sample’s details with your customer with inquiries like “how old is the sample?” “has it been sitting in the sun?” “has it been subject to any alteration over time?” It may not occur to customers that there are variables that could have affected the sample they provided and what you measure is what they’ll get. Gather as much information as possible, so you can unlock the product’s full potential on the first go-round.

2. Keep the Sample Clean

A dirty sample from highly-trafficked areas like wall corners, baseboards, hallways, and stairwells may not produce an ideal color due to the inevitable build-up of daily grime. Ensuring a sample is as spotless as possible upon receipt will save considerable effort on preventable corrections.

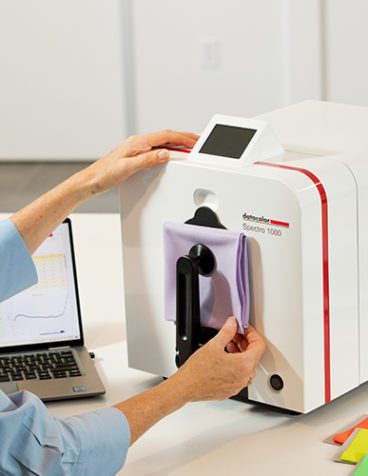

3. Manage your Maintenance

Although spectrophotometers and dispensers require minimal maintenance, that little bit of extra care can go a long way. Spectrophotometers should be regularly calibrated. Dispensers are at their most accurate when there is no colorant build-up, so manufacturers generally suggest a daily purging to avoid clogging. Treat your equipment right, and it will return the favor!

4. The Perfect Match

Have you ever matched a color and had Delta*e and metamerism numbers pop up? In case you were wondering, the lower the number is, the closer you are to your target color. Delta*e is the visible measure of change between two colors. Metamerism is the visible change between two colors across different light sources.

5. Embrace the Barcode Scanner

Sometimes you become so deeply immersed in your operation, or you have become such an expert, that your brain can switch to autopilot during certain activities. This is where a Barcode Scanner comes in handy. When all those paint cans start to look the same, the scanner is your assurance that you’ve picked the right base each and every time.

We understand that even with these practical suggestions, a mistint can occasionally occur. If that happens, our biggest piece of advice is to put your color matching computer to work. Should a correction be out of your reach, Datacolor’s best-in-class matching technology will provide a new, upgraded formula that will administer the color you need.

Still need more information? Chat with one of our retail paint experts!

Connect with a Color Expert