This article was originally published on LinkedIn by Jason Loehr on July 2, 2020.

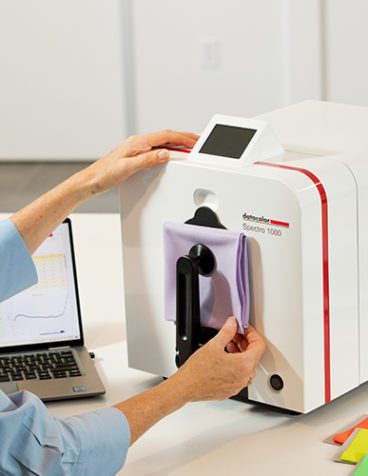

In the paint and coatings industry, color can be surprisingly difficult to get right, especially because we all see color differently. And because speed-to-market is more important than ever, inaccurate color measurements can delay product to market and increase business costs. Having the right technologies and tools in place is essential for an effective color control process.

And while the value of these technologies is becoming increasingly appreciated across the paint and coatings industry, the COVID-19 pandemic has further emphasized the need for a digitalized color management workflow. Industries continue to shift to adhere to social distancing mandates and protect the safety of their workers while still producing essential materials. Companies and manufacturers in the paint and coatings industry are learning that many jobs can be done differently than before and in a variety of locations, making technology and digitalization critical to workflows. Now, more than ever, we are leaning on technology to drive our industries forward.

Thankfully, color management technology has been evolving to not only meet the current needs of the industry, but also the considerations of tomorrow. Here are three things shaping the future of color control technology as we know it:

- The evolution of color management solutions, including exceptional IIA and the introduction of hyperspectral spectrophotometers

- The revolution of portability

- The introduction of cloud-based software

To learn more about these three items and how they will impact color management processes, check out my latest article published in the June 2020 issue of Polymers Paint Colour Journal (Page 15: “The future of colour management: Three things shaping colour control technology”).

Color can be difficult to get right; however, with the right tools and technology, you can establish an effective workflow that translates into accurate color every time.