Top Ahiba Details

- High accuracy and repeatability – State-of-the-art microprocessor control and sophisticated algorithms ensure temperature regulation at every step of your process.

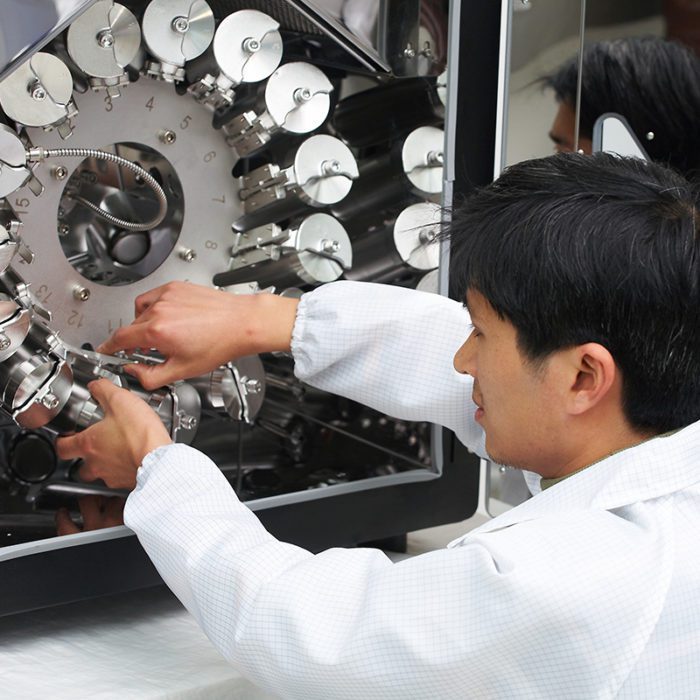

- Improved productivity – Intuitive multi-language user interface easily recalls up to 99 locally stored programs that quickly match production processes. Up to 20 dyeing positions in the dyeing unit ensure that a large number of samples can be dyed accurately. Dosing options are available for swift addition of liquid or powder auxiliaries during the dyeing process.

- Wide application support – Multiple beaker sizes and dual agitation methods to meet the widest range of textile dyeing applications.

- High efficiency and low environmental impact – High efficiency infrared lamps, circulation fans, and a sealed dyeing compartment guarantee that the radiant temperature transfer from chamber to beaker is optimized. Smart industrial design and modern materials improve safety of operators, and reduces heat loss from the dyeing chamber, making the Datacolor Ahiba one of the lowest powered units on the market.

*Patent information

What You Get

- One full set of dyeing beakers and beaker wheel as ordered.

- If dosing beakers are ordered then all associated dosing parts will be included in the assembly.

- Beaker lid closing tool

- One spare bayonet PT-100 sensor

- One preparation basket equal to the beaker size ordered. (IR Pro – Only)

- One spare set of lid o-rings

- Set of spare fuses (included inside rear cover of the unit)

- USB Flash Drive (includes:)

- PC Application Utility installation program (IR Pro – Only)

- User manual

- Other Documentation

- Quick Start/Installation Guide

- Conformance documentation

- QC Testing Documentation

Technical Specifications

| Features Comparison |

AHIBA IR |

AHIBA IR PRO |

| Fibers Types |

All |

All |

| Substrate Types |

All |

All |

| Multiple Beaker Size Configuration |

|

|

| Wash-Fastness Simulation |

|

|

| Minimum Liquor Ratio |

1:5 Natural – 1:4 Synthetic |

1:5 Natural – 1:4 Synthetic |

| Temperature |

|

|

| Display Temperature in C° or F° |

|

|

| Temperature Range |

20° – 140°C |

20° – 140°C |

| Heating |

|

|

| Infrared Lamp |

3KW |

3KW |

| Heating Gradient |

+5.0ºC/min |

+4.0ºC/min controlled |

| Beaker-to-Beaker Accuracy |

±0.5ºC |

±0.5ºC |

| Heating accuracy: isotherm |

±2.0ºC |

±1.0ºC |

| Cooling |

|

|

| Cooling System |

Air |

Water/Heat Exchanger |

| Movement |

|

|

| Speed |

5-50 selectable |

5-50 selectable |

| Reverse Rotation |

Yes-automatic |

Yes-selectable |

| Dosing |

|

|

| Manual Dosing (injection or membrane)° |

|

|

| QuickDose |

|

|

| Controller |

|

|

| Controller Type |

Microprocessor Control |

Microprocessor Control |

| Calibrated Temperature Accuracy |

<1ºC |

<1ºC |

| Dyeing Temperature Control Accuracy |

<±2ºC |

<±1ºC |

| Controller |

|

|

| Touchscreen |

– |

|

| Display Color |

Monochrome |

Color |

| Program Storage |

99 programs |

99 programs |

| Display Program Graphs |

– |

|

| External Program Storage |

– |

|

| Record Program Data |

– |

|

| Controller Multi-Language |

– |

Yes (7 languages) |

| Delayed Program Run |

– |

|

| Manual Mode |

– |

|

| History File |

– |

|

| Multi-Level User |

– |

|

Installation requirements

The systems should be installed on a sturdy table or benchtop in a laboratory environment with temperature and humidity conditions:

5°-31°C with <80% rH

31°- 40°C with <50% rH

Electrical supply: 230 V, 50/60 Hz Single phase, 3 wire (Line, Neutral, and Earth Ground) tolerance of <+/-10%.

Heating Power: 3000 W

Total Power: 3850 W

If the mains supply is prone to interruptions and failures a UPS is recommended.

AHIBA IR PRO

The unit is water cooled, Use only filtered and softened water.

Pressure: 2-3 bar (30-45 psi)

Hardness: <10 dH

Temperature: Ideally <15C

Hose: Min. diam. 3/8″ (10mm), Hi Temp.

AHIBA IR

The unit is air cooled, ensure at least 12” clearance behind unit for air exhaust