The impact of global events over the last several years have touched every corner of the manufacturing sector, and the plastics industry is no exception. Disruptions caused by increasingly severe weather, international and regional conflict, and political uncertainty are forcing supply chains to adapt and pushing business leaders to reimagine traditional processes, paving the way for digitized solutions.

A recent Fictiv State of Manufacturing Report notes that fully 99 percent of supply chain decision-makers around the world believe a resilient supply chain is critically important, yet only 17 percent rate their company’s supply chain resilience and adaptability as exceptional. What’s more, 87 percent of supply chain decision-makers surveyed indicated their company’s transformation to a digital workflow is a high priority.

For an incredibly complex industry like plastics, an agile supply chain is paramount. Add color into the mix, and the need to adapt quickly is crystal clear. Color is a vital element that touches every stage of plastics production, from the earliest design concept to the finished product. A digital color management workflow can help plastics suppliers and manufacturers lower production costs, save valuable time, and reduce environmental waste.

The Complex World of Plastics

Plastic—a shortened form of the word thermoplastic, meaning polymeric materials that can be shaped and reshaped using heat—is one of the most ubiquitous objects of modern life. Just about everything we touch has plastic in it, from water bottles and cell phones to clothing and furniture. We find plastic in our computers, our plumbing pipes and our children’s toys. Even everyday items that don’t contain plastic, like stainless steel, glass or wood, are typically encased (and often shipped) in plastic packaging.

Whether the end product of a supply chain is resins and pellets—the building blocks of nearly everything made of plastic—or a multi-component consumer good found on retail shelves, the color process is anything but simple for the plastics industry. The sheer variation across plastic materials is head-spinning: opaque, transparent, matte, high gloss, metallic, pearlescent and so on. Each has an impact on how a colorant can be applied and how it looks in the real world. What’s more, many plastics must coordinate color with disparate materials, like textiles or leather, to create a cohesive palette. (Think of the interior of your car.)

Adding to this complexity is the need to make accurate color decisions quickly and cost-effectively, even when suppliers and manufacturers are stationed half a world apart. Or in today’s climate, when workers are conducting business remotely from home offices scattered across the globe.

Remote Color Decisions for Plastics

The plastics industry operates via supply chains spanning multiple locations, requiring decision-makers to traverse continents in order to evaluate color samples in person. Moving toward a digital color workflow can dramatically reduce the need for wasteful samples, cut down on unnecessary travel, alleviate painful bottlenecks and avoid costly delays. More than ever, color management requires precise equipment and flexible software to foster data-backed decisions from anywhere in the world, at any time.

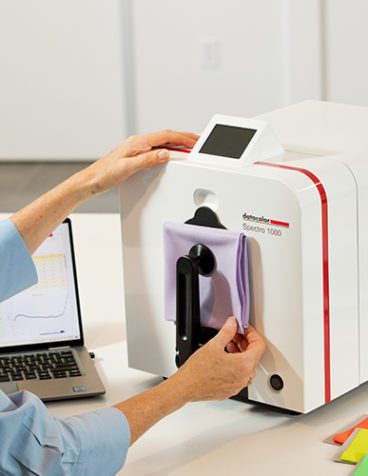

A suite of Datacolor solutions can address the unique constraints of evaluating color on plastics remotely. Given that we all see color differently, a spectrophotometer is a must-have tool for streamlining decisions about color and facilitating greater transparency across the supply chain. Two products in particular, the Datacolor 45G and the Datacolor Check 3, put the spectrophotometer right in the decision-maker’s hand—literally. Remote workers can use these portable devices to make critical color decisions from anywhere.

And because our eye perceives color differently on glossy surfaces, both of these instruments are equipped with Gloss Compensation technology, which measures specular reflection, calibrates the data, and adjusts the color formula to account for surface sheen. Meanwhile, our Colibri software helps users create a color recipe that suits the requirements of the specific plastic, whether the pigment needs to be weather resistant, food safe or light-fast. Another game-changer, Gamut Mapping, reduces the time-consuming trial-and-error process of running multiple formula combinations by alerting the user in advance which colorants are unable to match the desired target. All of these software solutions can be accessed in real-time from anywhere in the world, facilitating quick and accurate decisions virtually.

Plastics and Sustainability

Top of mind for consumers and plastics manufacturers alike are the environmental implications of plastics production. A resurgence of single-use plastics has created fresh challenges from a sustainability perspective. But, is there a way to make plastics production less wasteful? There’s no question that portable spectrophotometers and color software solutions save time and money; these tools can also reduce the plastics industry’s impact on the environment.

Perhaps most impactful, digitizing color means producing fewer physical samples, and fewer physical samples means less waste and less pollution from dyestuff. And, instead of hopping on a plane or shipping those samples overseas for evaluation—turning up the notch on fuel use and carbon emissions—plastics companies and manufacturers can communicate color decisions digitally, achieving greater accuracy while leaving behind a smaller carbon footprint.

Plastics Case Studies: Streamlining Color in the Real World

Many of our plastics costumers have streamlined their color management workflow, increased the accuracy and efficiency of their color decisions, and reduced their costs. Their successes in the face of everyday challenges can serve as a model for navigating color within the constraints imposed by the pandemic.

SEKISUI Polymer Innovations utilizes a suite of Datacolor products and services to manage color quality control for a diverse array of industries, including aviation, transportation and medical devices. SEKISUI SPI’s niche customers demand precise color in a tight timeframe. Our team works closely with the global thermoplastic manufacturer to ensure delivery of accurate color decisions at impressive speed.

Thai-based Pioneer Industries, which specializes in injection molding and package printing, turned to Datacolor to support the expansion of its local customer base in Thailand. Combining a powerful spectrophotometer with state-of-the-art software allowed Pioneer to automate its color recipe creation and enhance the accuracy of its color matching—all while reducing its waste output by 600 tons, saving the company $600,000.

Munich-based auto industry powerhouse BMW Group worked with Datacolor to reduce the color development time for its car interiors by 50 percent. By implementing a digital color development process, BMW significantly improved its color coordination quality across various surfaces, dramatically reduced the need to create physical samples, realized impressive cost savings and increased its speed to market.

It’s safe to say the new normal is here to stay. Plastics suppliers and manufacturers who adapt their supply chains to meet today’s need for digital color management will decrease costs, increase speed and efficiency, ensure quality and reduce environmental waste. Our team is here to help you find the solutions that are right for your business.

Contact us to learn more