The

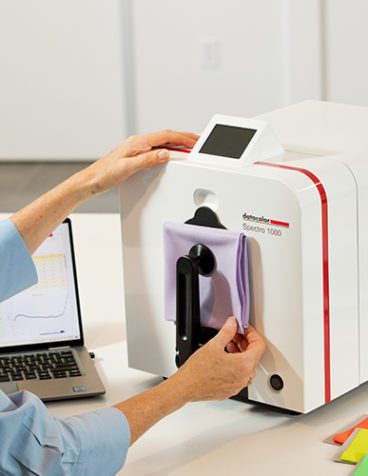

AUTOLAB TF automated recipe dispensing system is an invaluable addition to color labs where speed, accuracy and repeatability are critical. It automatically dispenses dye recipes fast so you can focus on productivity—and avoid expensive re-dyes. And it also runs virtually non-stop thanks to auto-feeding conveyor systems and “calibration-free” injectors.

Whether you’re using your AUTOLAB TF dispensing system for exhaust and continuous dyeing, textile printing, floor covering, pigments or one of its many other applications, proper operation and care is important for accurate and repeatable dye results. Here are our best practices for keeping your system running efficiently and effectively.

Get our Free Ebook: Fundamentals of Color

Get our Free Ebook: Fundamentals of Color

Follow AUTOLAB Maintenance Recommendations

Any mechanical system needs routine and preventative maintenance. A simple checklist lets you track which procedures have been completed and see which employee has done the work. We also recommend that you maintain a logbook to easily identify any operator problems.

A single person should be responsible for overseeing the system. That person can ensure that maintenance takes place on schedule and can take steps to resolve any recurring problems.

Learn More About Our Textile Industry Solutions!

Pay Attention to Water Quality

Water is used to make the dye solutions and also to dispense dye recipes. Problems with water quality will affect solution stability and repeatability of dyeing.

- Filter the water: The 5 micron filter supplied with the system is designed only to remove large dirt particles. To eliminate smaller particles including algae, a specialized 2-micron filter might be required. De-ionising and de-aerating filters are also available. (Our hardware support team can help you purchase one of these filters).

- Kill bacteria: If filtering is insufficient, chemicals like Zeneca or hydrogen peroxide may be required to kill algae or other bacteria. These can be added within the dyestuff solutions and used to clean the dispensing tubes.

- Be consistent: The water used in laboratory work needs to be similar to what’s used in production. This will ensure the closest color correlation.

Care for the Dyestuff

It may seem obvious, but repeatable results depend upon proper handling of the dyestuff.

- Use the proper solution strength: Every dyestuff has a maximum solubility level. Solutions must be prepared at consistent solution levels and never at strengths higher than the manufacturer’s recommendations.

- Pay attention to shelf life: Discard dyestuff solutions that have gone beyond their shelf life. AUTOLAB software provides a warning when any solution is out of lifetime. System operators need to follow those warnings.

- Ensure stability: Besides water quality, chemical additives can help ensure dyes remain stable throughout the longest possible shelf life. Follow the manufacturer’s recommendations to add dispersing agents, acids, or other chemicals for particular dyestuffs.

- Prepare solutions correctly: An advantage of using AUTOLAB is that standard solutions can be programmed into the system. To be effective, through, the initial inputs must carefully follow the manufacturer’s directions. Acid dye solutions, for instance, require different initial water temperatures than disperse dyes. Incorrect preparation can lead to unstable solutions and incorrect solution strengths.

Transform the Way You Handle Dye Formulations

Consider Physical Conditions

For best results, various dyestuffs require different handling.

- Storage: Light-sensitive dyes are best stored in brown solution bottles to prevent light from degrading the dyestuff.

- Physical positioning: Disperse dyes aren’t true solutions, so can settle over time. These dyes should be positioned where dispense tubes are shortest, or just above the dispense heads.

- Cleaning: Most dispense tubes can be easily cleaned by following daily and weekly maintenance guidelines. Datacolor recommends additional procedures if you’re using disperse dyes, however.

For additional questions about operating and caring for your AUTOLAB TF, don’t hesitate to contact our team.

Ready to learn more about our full suite of solutions for color measurement, formulation, communication, lab dyeing and dispensing, visual assessment and more?

Discover what Datacolor can do for you!