What I’ve Learned About Implementing an Efficient, Cost-Effective Color Program

This is a guest blog from Dory Newman, Owner of Color Remedy Consulting. Over the course of her career, Dory has been involved in the color programs of Talbots, Coldwater Creek, Macy’s, Ann Inc. and Ascena Retail Group. Now, at Color Remedy Consulting, she pulls from her over 20 years of industry experience to help companies optimize their approach to color management.

While there’s never a bad time to evaluate the success of your color program, I tend to work with clients that are already having a problem with their color operations. For example, vendors have consistent issues achieving the color target within tolerance.

And while that’s certainly a problem, usually there’s something bigger happening under the surface. It’s my job to investigate their processes and technology and figure out what’s really causing color-related bottlenecks behind the scenes. Many times, this kicks off the search for new equipment. It’s also a chance to re-think their processes and figure out a more efficient way to work with color.

If you’re looking for ways to improve your own approach to color management, I wanted to share what I’ve learned from more than 20 years working in color. My hope is that it will help you make the right decisions when implementing new color technology and establishing updated processes — so you can fix the issues that are slowing you down and costing you money.

You Don’t Know What You Don’t Know

I remember a specific story from early on in my career: I was looking at a black cashmere lab dip and because of a lack of communication within the team, I didn’t know that it was multi-sourced. So the same cashmere color was being done by several different mills. The yarn was different even though it was supposed to be the same color, and no one on the team let me know until it was too late in the approval process. As a result, there were eight different blacks in store for the company’s biggest-ticket item.

This may be an extreme case, but it shows the importance of understanding everything that’s going on with both technology and processes. Recently, I ran into a situation where a mill didn’t know about QTX files and how to use them as standards. The color team advised them what standard they wanted from a book. Instead of ordering the QTX file from the company that produced the color, they were just reading the chip from the book, which was likely old and had likely changed color with age. The worst case scenario happened: All of the colors were out of tolerance and couldn’t be approved because the tools were being used incorrectly.

The cost of these mistakes can be significant. Usually, if you can catch the problem in the lab dip stage, you won’t have the problem in bulk. But if a bulk was done wrong and you need to cancel the order, that’s a huge expense. You want to have your lab dips approved as quickly and efficiently as possible to keep costs down.

Companies typically aren’t charged per lab dip, but it ends up on the cost sheet somewhere. So if you don’t implement color technology that helps everyone match the same color and make it quickly and efficiently, the math can get out of hand fast. Think about if you end up going 12 rounds trying to achieve a color that should have been approved on the first round. On average, lab dips cost between $150 to $200 a round to produce. That’s upwards of $2400 to get a single color right.

I’ve also seen cases where a bulk color is submitted off and the team doesn’t like it, so it needs to be redone. Those costs are even higher. These things tend to happen most when there isn’t a good color program in place.

Working Towards a Solution

There are a few pieces of information I start with any time someone comes to me with a color management problem:

- What their current process look like

- Who they have on their team

- Who is making the decisions

I also want to know where their mills are and what color service providers they use, if any. I want to know if they’re open to trying new things with their approach to color.

Here are some additional questions to ask specifically related to colorists:

- Do they have a trained colorist on the team?

- Does that colorist understand how to correctly communicate with overseas AND internal teams?

- Does the colorist have the capacity to drive process, train vendors and influence internal teams?

- Is the Colorist open to working in a new way?

If the answer is “yes,” to all of the above, we move onto more details. What kind of product do they work on? If they’re only doing athleisure, maybe a cotton standard isn’t the best fit and a poly or nylon one is better. That could be a key reason why they’re not getting good color consistency.

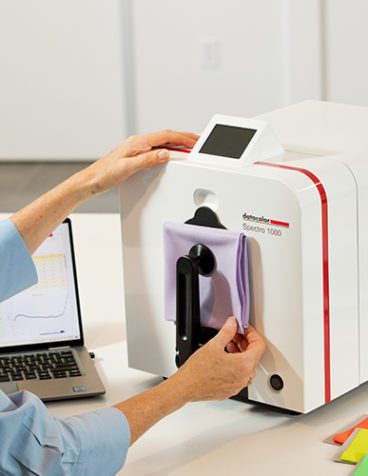

Then we’ll move onto talking about technology. Do they have a spectrophotometer? A lightbox? Have they specified a light source for their vendors? A lot of times, companies are using an old incandescent light source, which isn’t used anymore. Are they open to or do they have the budget to invest in technology?

Then, I want to know what their calendar and budget look like.

Understanding a company’s current process as well as possible is the best way to set them up for success going forward. Change management with color seems to be one of the biggest hurdles when implementing something new. A lot of times this is because designers or merchants are more comfortable with visual approvals and trust the human eye more than a computer.

Sometimes Spectrophotometers Get Bad Raps

If you’re new to the world of spectrophotometers, I can see how they might feel like an unnecessary expense at first.

Often, it isn’t until you’re using them that you see the tremendous payoff: time saved, money saved, and quality improved. Plus, there’s no one-size-fits-all instrument. There are a lot of options out there to suit different applications. If you don’t choose one that’s right for your company, your initial negative perception of spectrophotometers will be correct.

Finding the right fit requires careful consideration of your product and your end consumer. If you’re a table linens company, you’ll need a different solution than a high-end women’s wear specialty store. Not everyone has had a chance to travel overseas, so it’s important to discuss what happens on the mill side when it comes to technology. If you haven’t visited a mill before, it’s hard to see the implications of rejecting the fourth or fifth round of lab dips or bulks and what that means for the production process.

What it comes down to is showing how good things can be between brands and mills with the right technology and processes in place — how efficient you can make things and what it looks like when lab dips are approved within tolerance on the first round.

Sometimes, vendors get a bad rap, too. It’s easy to blame a mill for not being able to do a match when the problem actually happened on the customer side. My goal is to help companies understand that they can get to a place where they trust the mill to do their approvals and empower them. Because when you get to this point, the time savings are dramatic.

Spectrophotometers are Easier to Use Than You Think (I Promise)

I don’t just hear hesitations around cost. I’ve also heard from companies that it’s not important to use color standards and it’s not important to use digital color data. A lot of this arises from the perception that managing color on a computer is a difficult, extremely technical process. I promise it isn’t. The reality is that the human eye has limitations. But the computer will measure the same day after day. Numbers do not lie. There still needs to be a check with the human eye, but there is no denying that reading color into a computer needs to be part of an efficient process.

Digital color technology isn’t for every single product out there, or for every line, but there are many places where it can improve the speed and efficiency and accuracy. And that in turn saves time and energy for colorists to do other projects and become more well-rounded associates.

Implementing New Color Technology: Getting the Right People Involved

Getting color right is a many-person, often-global operation. That’s why it’s so important to get the right stakeholders involved when you’re working to implement new technology.

First on that list of people? A colorist — someone who is responsible for reviewing and approving colors. You also need someone more junior who works with color, whether it’s design, merchandising, or another role. This is because they’re the ones doing the day-to-day work and can speak to current bottlenecks in detail. You also need senior executives to buy into the investment and help reinforce change management from the top down.

Three Things to Do Before You Make a Technology Investment

You need the right people, but you also need to approach your technology research in a smart way. Thinking back on my 25-plus years working with color, these are the things I think all companies should do before they make a final decision on a color measurement instrument:

- Test out your options. I think testing out some of the products on the market is the best thing you can do. You need to make sure you see the different technologies that are available and carefully consider which one is the right fit for your needs.

- Consider customer service. Especially when you’re implementing new technology, you need the support of the company, so you want to make sure that’s available.

- Make sure you have the right people on staff for a successful program. I’m a big believer in having somebody on your team who is strictly for color. At the very least, you want to have someone shared between color and fabric, color and production or color and QA.

Advice for Adjusting to a New Way of Working with Color

There are bound to be some roadblocks as you switch from the old way to the new way of managing color. But if you can anticipate some of them, it’ll be easier to stay on track.

Change management is often the biggest roadblock. I think people are really resistant to change, and color management is no exception here. People also tend to get hung up on technology, especially in the fashion world. Designers like to create by sketching or choosing fabrics at a fabric store, and they’re afraid that if they relinquish that to a computer, their quality or beautiful aesthetic will go away. In fact, it’s the opposite. Technology can help bring their vision to life far better than a visual-based approach.

The second biggest challenge I see is not managing the process enough. Even the best technology will let you down if you don’t have a solid process behind it. At most companies, there are different levels of education and ability when it comes to working with color. Some companies have a document that was made in 1988 and just needs to be updated with current light sources and new color service provider information.

But then there are some companies that haven’t had a true process before. In these cases, you need to start from the beginning. You might need to start by getting everyone comfortable with a lightbox and educating mills on the light source you want to use. Here, I’d recommend focusing only on using the right light source for a season.

After that, phase two is getting designers to use color standards from a color service provider. In addition to checking and making sure everybody is still using their light boxes and still using the right light source, now you’re notifying them of what color standards you want and making sure they’re buying them — not just using them from an old book of swatches.

Change Beyond the Home Color Office

I’ve alluded to it throughout this article, but making sure your new color program runs smoothly requires a partnership with your overseas vendors. Whether it’s a mill or a factory, they’re your eyes on the other side of the world. You can make all the decisions you want in your office in New York or Ohio or Florida, but you need someone where the production is to really reinforce the partnership.

This is where vendor empowerment comes in. Including them in your journey really helps. Usually, I’ll do this in a phased approach. Start with the smallest-risk part of the process and have them do their approvals there so they’re part of your team. Getting to a place where you trust each other is key.

The Takeaway? Investing in Color Technology is Worth It

Will you see the benefits of your investment overnight? Maybe not. You really need to go through a whole production cycle to know what works. At some companies, adoption happens quickly and the team starts buying color standards and moving things along efficiently. At other companies, it takes longer to get everyone on board.

My biggest goal is to show companies that they shouldn’t be afraid of color technology. It exists to help you. The solutions that are out there are easy to implement and use and they’re easy to train others to use. You just have to be willing to make that leap and do it.

I can help a company throughout the process and set them up for success, even if they don’t have the in-house knowledge.

Connect With a Color Expert!