Zhangjiagang Yangtse Spinning Co., Ltd. is a Sino-German joint venture located in the Zhangjiagang Economic Development Zone. As a production base established in China by Südwolle Group, a large producer of worsted yarns, it boasts advanced equipment and technology and plays an important role in the international spinning industry.

Traditionally in the textile printing and dyeing industry, color evaluation is left to employees’ eyesight alone and color control mainly relies on the physical transfer of information between people. This results in an inability to respond quickly to production requests.

This presents a clear opportunity for digital color management.

However, as the most traditional field of color application, the textile printing and dyeing industry has stringent requirements for fabric color in terms of measurement, evaluation, recipe prediction and control, as well as digital management of product quality. These challenges need to be solved by enterprises that want to achieve a digitalized production process.

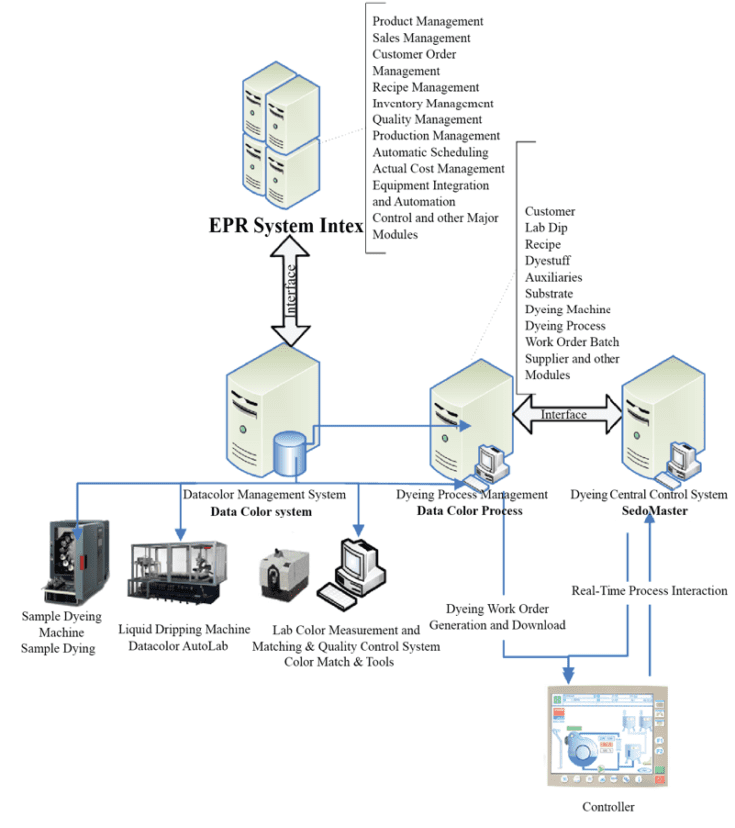

When a textile enterprise wants to transition to a digital approach to production, they must implement a full suite of intelligent printing and dyeing control systems. This includes not just basic systems such as an Enterprise Resource Planning management system, dye matching system and central color control system, but also a color management system.

This final component is where Datacolor was able to help Yangtse. We collaborated to build an intelligent system for coupling design and production. This includes color matching software and equipment supported by Datacolor’s professional color management knowledge.

Throughout the design and production coupling process, Datacolor’s color management system played a pivotal role. For example, Datacolor’s Autolab machine can automatically dispense dyestuff based on a designed recipe. With a wide range of solution bottle options, it can dispense a variety of viscous solutions that are suitable for applications from exhaust and continuous dyeing to textile printing. viscous solutions that are suitable for applications from exhaust and continuous dyeing to textile printing.