Datacolor Process, Ticket, and Weigh

Datacolor Process

A sophisticated production management and recipe optimization solution designed by dyers – for dyers. It uses the knowledge of your company experts to help manage, automate, and optimize your dyeing recipes and processes ensuring that production costs are kept low without compromising on color quality or ecological demands.

Datacolor Process Pro

All the great benefits of Datacolor Process plus increased automation for dyestuff data management, recipe and dyelots evaluation based on process costs, customer’s specific processes and advanced formulas for inventory delivery and reservation as well as dye orders and options for grouping dye lots with the same recipe.

Datacolor Ticket

An entry level, easy-to-use software package that records and manages dyehouse production recipes. Immediate access to all recipes, allows users to create and calculate production dye lots, without the need for manual filing systems and calculations.

Datacolor Weigh

Fully integrated to our production recipe management systems Datacolor Process and Process Pro, this controlled weighing software package interactively guides operators through the entire weighing process of chemicals, auxiliaries and dyestuffs and sends real weight information from the connected scales to the system.

Get a Demo

Software Specifications

| FEATURES COMPARISON |

DATACOLOR TICKET |

DATACOLOR PROCESS |

DATACOLOR PROCESSPRO |

| Data Management |

| Folder structure |

|

|

|

| Grouping function in lists |

|

|

|

| Dyestuff data Management |

| Input of dyestuff data and dyestuff exchange |

|

|

|

| Automatic checking of dyestuff combinations |

|

|

|

| Quality Management |

| Input of quality, sub-groups and blends |

|

|

|

| Input of quality specific correction factors, processes & parameters |

|

|

|

| Input of quality specific auxiliaries and quality level support |

|

|

|

| Color Management (standards/references) |

| Production History for each color and recipe history with pass/fail data |

|

|

|

| Customer Management |

| Input of customer data and listing of customer specific colors |

|

|

|

| Recipe Management |

| Storage of recipe status, and search via different criteria |

|

|

|

| Automatic recipe update by change of dyestuff concentration |

|

|

|

| Recipe evaluation based on process costs |

|

|

|

| Relative additions of dyestuff concentrations |

|

|

|

| Default recipe parameters |

|

|

|

| Recipe templates (sup operations and dyestuff placeholders) |

|

|

|

| Process Management |

| Creation of modular production recipes |

|

|

|

| Handling of exhaust continuous and semi-continuous processes |

|

|

|

| Specific linked processes for production adds and re-dyes |

|

|

|

| Input of customer specific processes (e.g.: add washing for customer xy) |

|

|

|

| Automatic operation selection through defined rules: if-then-else rules |

|

|

|

| Production Management |

| Batch ticketing (Advanced with additional information and expert with process times/curves) |

|

|

|

| Calculation of chemical /dye quantities for the dye kitchen |

|

|

|

| Selection of dyeing machine based on machine parameters |

|

|

|

| Lot-specific production parameter (e.g.: additional auxiliaries, specific start temperature) |

|

|

|

| Chemicals and parameters can be adapted for each production lot |

|

|

|

| History of production lots |

|

|

|

| History of production adds |

|

|

|

| Production cost calculation incl.: dyestuffs, chemicals and process cost |

|

|

|

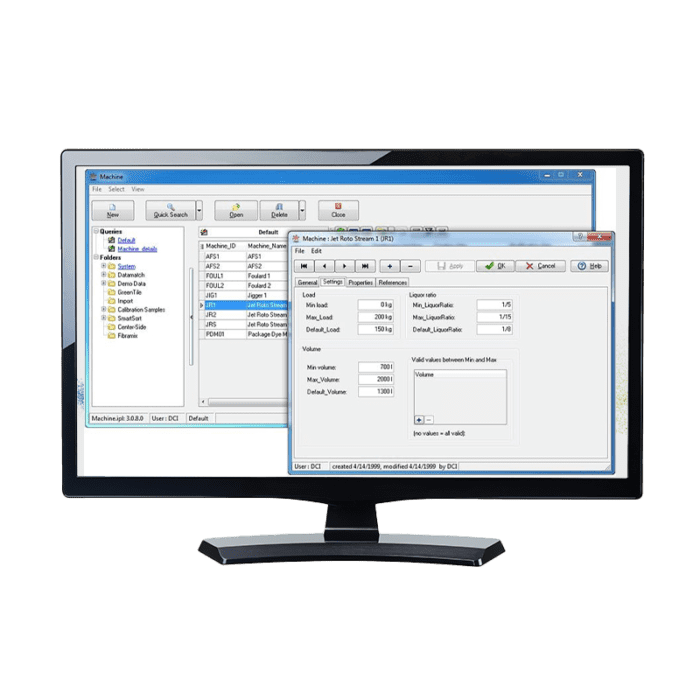

| Machine Management |

| Advanced Machine management option with min / max. load, liquor ratio, etc. |

|

|

|

| Advanced formulas |

| Advanced formulas like ‘In Case of’, ‘Table’,… |

|

|

|

| Expert Functions |

|

|

|

| Inventory: Basic Functions |

|

|

|

| Delivery and Reservation Option |

|

|

|

| Report Explorer: Report Editor |

|

|

|

| Recipe/dyelot Form Customization |

|

|

|

| User query and data Export to Text, HTML, EXCEL and xml |

|

|

|

| Dyeorder: Group/Split orders into dyelots with the same recipe |

|

|

|

| Graphical Planboard |

|

|

|

| Datacolor WEIGH controlled weighing option |

|

optional |

optional |

| Integration with ERP/Host, Dye Machine supervisor or production dispenser |

|

optional |

optional |

Talk to a Color Expert

Software Maintenance Support

Maximize Efficiency with Continuous Updates

Ongoing access to the newest features and color technology improvements, keeping you current and operating at peak efficiency.

Ensure Smooth and Reliable Performance

Compatibility with the latest operating systems and database technologies through regular updates; prevent out-of-date legacy issues and ensure smooth, dependable color management process.

Safeguard Your Operation

Benefit from enhanced protection on the newest platforms and most advanced threat prevention capabilities.

Consult with a Color Expert

Access to Datacolor’s color experts via phone and email for assistance and expert advice, helping you maintain precision and efficiency in your operations.*

Learn more about Software Maintenance Support

Customers on an active Software Maintenance Support plan can download the latest version of software.

*Software Maintenance Support excludes installation, training, and on-site support

System Requirements

| Component | System Requirements |

| Operating System | Windows 10 and 11 (Pro or Enterprise Only) |

| Required Framework | Microsoft .NET Framework 4.7.2 or higher |

| Processor | Dual Core or higher (See Windows operating system requirements) |

| Memory | 8 GB or more |

| Hard drive | 500 GB

For ToolsSV: SSD 1 TB Min, 4 TB

|

| Display | 1920x1080 - size of text only 100% supported |

| Graphic card | Graphic card supporting OpenGL 2.1 |

| Connections | Serial, USB, Bluetooth or Ethernet (depending on spectrophotometer model) |

| Server OS | Windows Server 2016, 2019, 2022 |

| Additional Requirements | Only for Paint 2.X: SQL Server 2022

Only for Tools 2.X: SQL Server 2012 to 2019

|

| Internet Connection | Internet access recommended for software updates and license activation |

| LAN Connection | For ToolsSV - Network should be 1 GBPS min |

| |

| Notes | Lower system configurations may limit performance, data capacity and operation of some features. Faster processor, more memory and faster hard drives will significantly enhance performance. |

Get Support